Quality and Fine Workmanship

Cases

As a fully integrated manufacture, we, at Patek Philippe, design and produce the cases for each and every one of our timepieces.

Materials

Have you ever wondered what the capital letter in all of our reference numbers represents? It is an indication of the watch case material, summarized by the first letter of its French designation. A subtle, yet elegant and effective way to provide an essential piece of information about each of our creations.

The Platinum Symbol

Platinum is a unique material in several respects: it is very rare, extremely pure, highly durable, its color doesn’t change over time, and it is particularly hard to work with due to the density of the metal. Therefore, we decided to add a distinctive touch to all our platinum cases by adding a diamond to each of them, inserted at 6 o’clock.

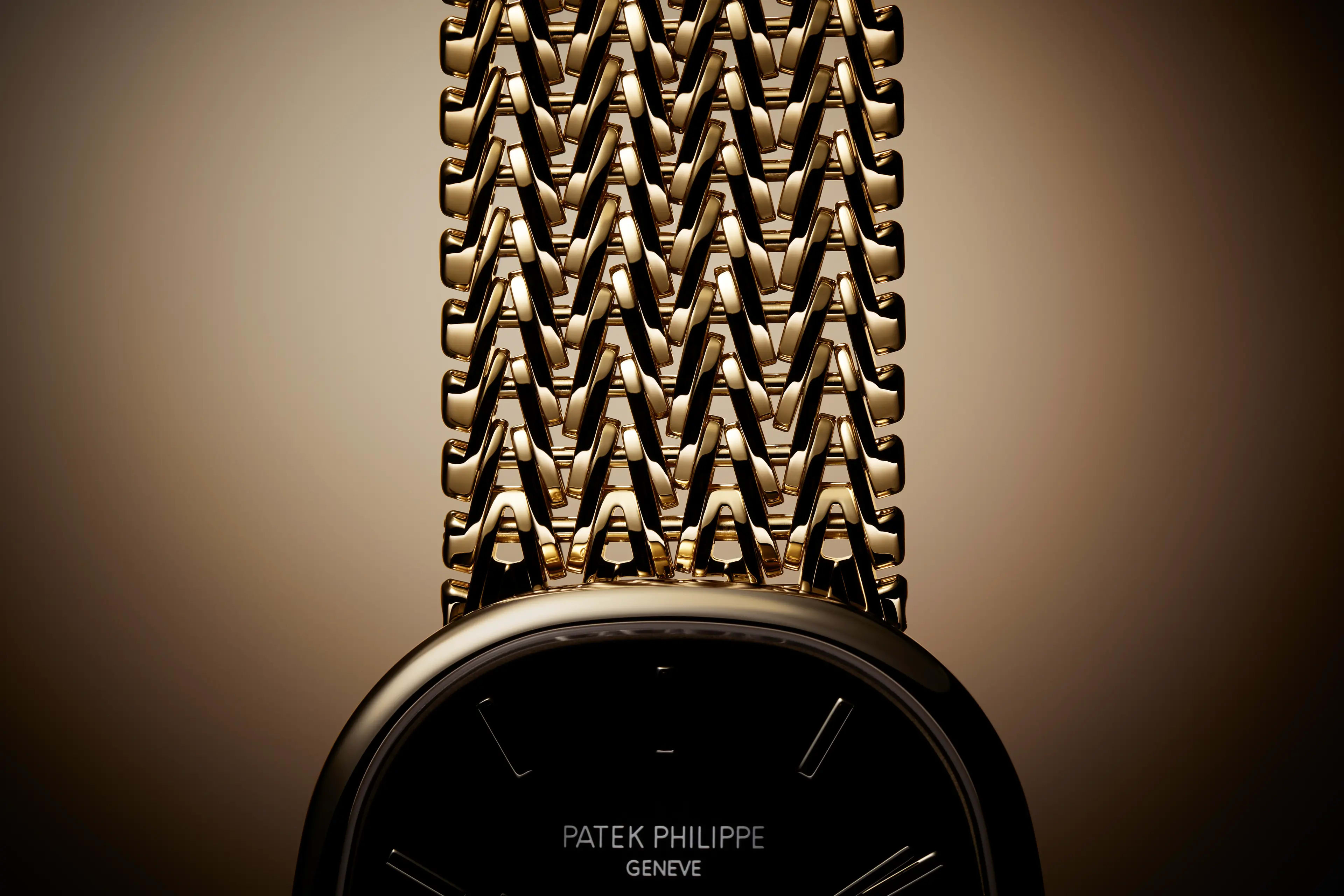

Shapes and Dimensions

While the majority of watches are round, we have distinguished ourselves for generations by manufacturing timepieces of various shapes and diameters to accommodate all types of wrists. In accordance with the strict principles of the Patek Philippe Seal, our designers are on a permanent quest to balance the thickness of our watches with their technical performance and energy efficiency.

Water-resistance

Adhering to the Patek Philippe Seal criteria, all our certified water-resistant watches are tested in air and underwater with a unified standard of water resistance by immersion at an overpressure of 3 bars (corresponding to a depth of 30 m). This measure makes it possible to guarantee the same performance level across all the models concerned and to provide comprehensible information regarding activities in which clients can engage while wearing their watch in water and during aquatic activities.

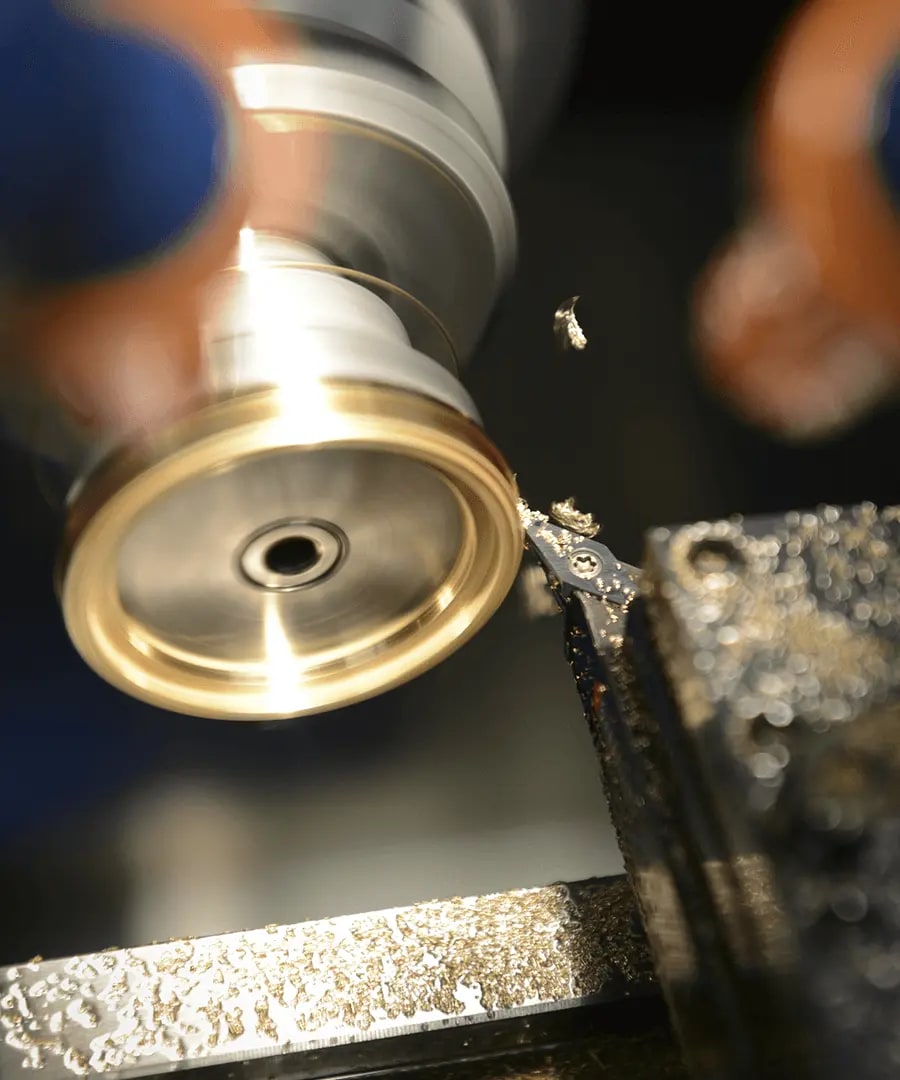

Creating A Case

Crafting one of our cases is a meticulous process, engaging nearly 20 specialists and involving around 50 distinct operations. This intricate procedure combines advanced machinery with artisanal skills, where the precise touch of human hands plays a crucial role in achieving the exceptional quality we are known for.

Cutting and Stamping

The initial step in creating a watch case is cutting the rough shape from a metal strip, such as gold, steel, or platinum. We exclusively use 18-carat gold, 950 platinum, and 316L stainless steel for our cases.

Then comes the stamping, when the cut case is refined through successive strikes at pressures of several tonnes to achieve its near-final shape. We stand out as one of the last manufactures that stamps its own cases, using custom striking tools developed in-house. This rigorous process ensures exceptional precision and quality in shaping each of our watch cases.

Then comes the stamping, when the cut case is refined through successive strikes at pressures of several tonnes to achieve its near-final shape. We stand out as one of the last manufactures that stamps its own cases, using custom striking tools developed in-house. This rigorous process ensures exceptional precision and quality in shaping each of our watch cases.

Machining

In this stage, numerically controlled machines refine the volumes and contours of the watch case, ensuring precise dimensions. Simultaneously, the serial number is mechanically engraved on the inside of the caseback, providing a unique identifier for each watch. This process, relying on advanced technology, enhances both the functionality and authenticity of the watch case.

Finishing

The final step involves precise manual executions, known as finishing. This process includes several key tasks: deburring, where material residues are carefully removed by hand; welding of the fasteners to ensure secure attachment points; and preparing the case for polishing. Additionally, the hinges are precisely shaped. Each of these steps is performed with great care to achieve perfect quality and appearance.

The different elements that make up a case (middle case, bezel, sapphire caseback, gasket, pushers) are assembled.