Artisans of Time

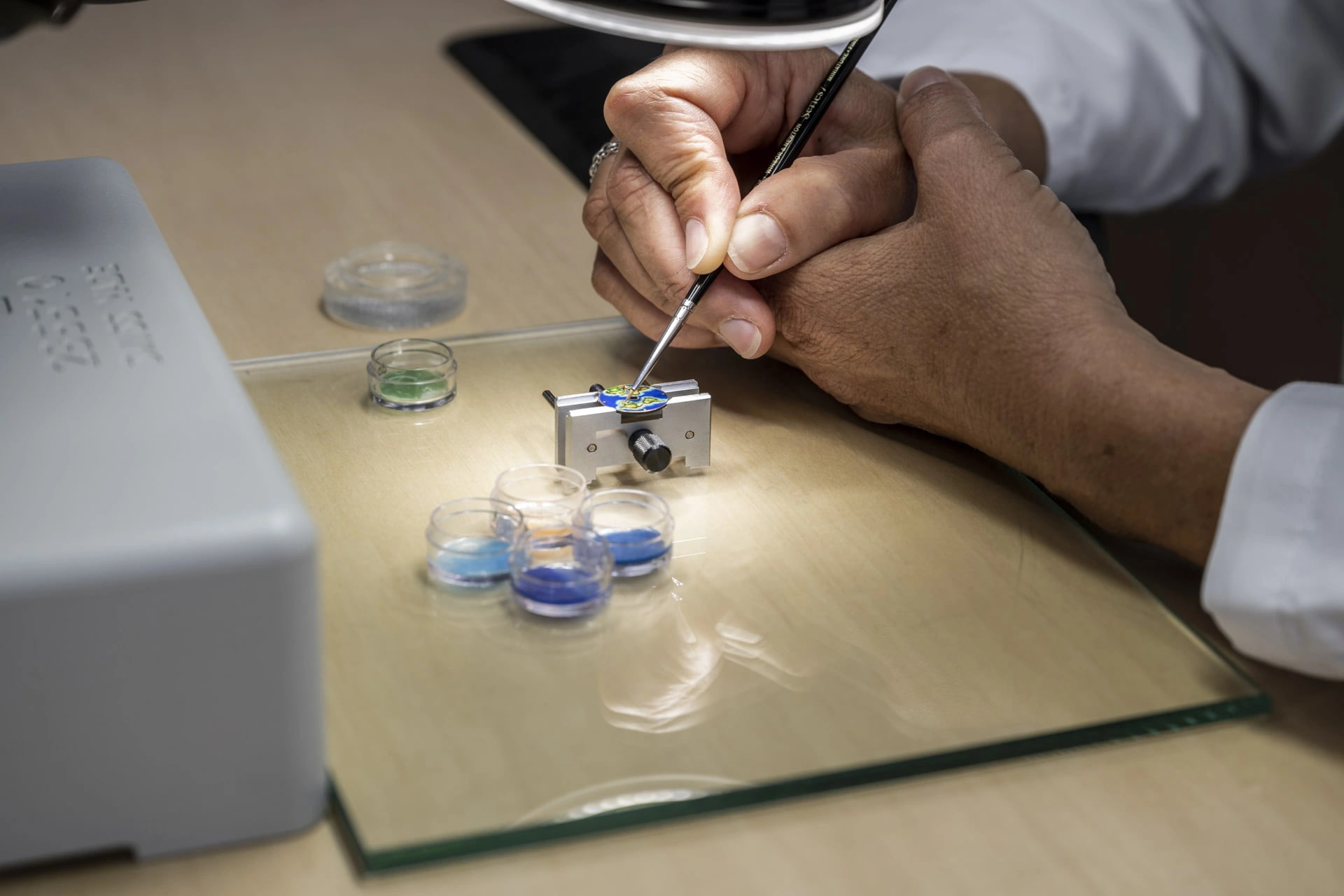

hand finishing

At Patek Philippe, our wide array of finishings and decorations are done by hand using age-old techniques that are considered some of the most demanding.

At our family-owned company, everything we do relies on the skills and creativity of our people. Very human skills that cannot be rushed or replaced. Only humans can accept the challenge to always push the limits of what is possible.

Impeccable human touch

Hand finishing is not only carried out for aesthetic purposes but because it allows us to increase the performance and durability of our watches. When performed on movement components, hand finishing takes on an extraordinary artistic dimension. Faced with surfaces that are so minuscule, our specialists are sometimes forced to resort to binocular microscopes.